BUSINESS

Material Matters: Selecting the Right Resources for Your CNC Parts

In terms of precision component manufacture, CNC (Computer Numerical Control) machining is the pinnacle of efficiency and accuracy. This cutting-edge method has transformed industries, allowing for the fabrication of complicated parts with unprecedented precision. However, every faultless CNC item is the result of an important decision: material selection. Indeed, material plays an important role in CNC machining, influencing not only part performance but also durability, cost-effectiveness, and overall quality.

In this post, we will look at the importance of material selection in CNC machining, including critical factors and guiding principles for manufacturers when selecting the correct resources.

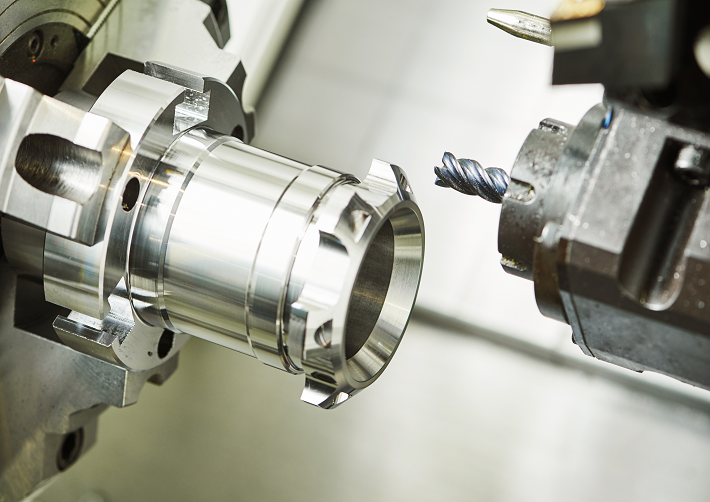

Understanding CNC Machining Technique

Before getting into material selection, it’s important to understand the principles of CNC machining. CNC machining, as opposed to traditional machining methods that rely on manual operation, uses computer-controlled automated tools. This automation enables the exact and repeatable manufacture of complicated geometries, making it vital in a variety of industries, including aerospace, automotive, electronics, and medicine.

CNC machining often begins with a digital 3D model of the intended product, which is then converted into CNC machine instructions (G-codes). These instructions direct the movement of the cutting tools across the chosen material, molding it into the finished result. Beyond traditional components, the integration of CNC parts into customized injection molding processes allows for even greater precision and customization. CNC machines may perform a wide range of machining operations, including milling, turning, drilling, and grinding, to meet a variety of production requirements.

The Significance of Material Selection

The material used has a significant impact on the performance and attributes of the finished product, showcasing the unrivaled versatility and precision of the CNC machining technique. Manufacturers must carefully consider a variety of aspects when selecting the best material for their CNC parts, including metals, plastics, composites, and ceramics. Key considerations include:

Material qualities

Different applications require material qualities such as strength, hardness, elasticity, and thermal conductivity. For example, aeronautical components may demand lightweight yet durable materials such as aluminum or titanium, whereas automobile parts may prioritize rigidity and impact resistance. The properties of the material play an important role in guaranteeing longevity and maximum performance. For example, to avoid overheating and signal deterioration, circuit boards require materials with exceptional electrical conductivity and heat dissipation capabilities. Due to its semiconductor qualities, silicon is still an essential element in microelectronics, allowing for the complex circuitry of transistors and diodes. Furthermore, a new era of materials engineering has been brought about by advances in nanotechnology. Here, materials such as graphene and nanocomposites offer unmatched strength, conductivity, and flexibility, completely changing the way that electrical devices are made.

Machinability

Not all materials are equal in terms of their ability to be cut, drilled, or molded during CNC machining process. Machinability is influenced by factors such as hardness, toughness, and thermal conductivity, with softer materials like aluminum and brass often being easier to machine than hardened steels or exotic alloys. Moreover, machinability factors go beyond just cutting simplicity. Important considerations are surface polish and dimensional accuracy, especially in precision engineering applications such as medical devices and aircraft. Softer materials may be more tolerant of machining errors, but if not treated carefully, they may distort and develop surface irregularities. Harder materials, on the other hand, might need specific tooling and cutting methods to obtain the required precision without reducing tool life or jeopardizing the integrity of the finished component. Optimizing manufacturing processes and guaranteeing the quality of the final product entail striking a balance between machinability and the unique needs of the application.

Cost

Material costs have a substantial impact on manufacturing economics, influencing overall production costs and part affordability. While some materials may provide better performance, they are often more expensive. Balancing performance needs and economic considerations is critical for optimizing manufacturing budgets. Furthermore, a variety of factors, including availability, market demand, and geopolitical developments, might affect the cost of materials. Price changes can have a big effect on profit margins and competitiveness for businesses that depend heavily on large amounts of raw materials. Consequently, to reduce cost volatility and uphold quality standards, manufacturers frequently look for substitute materials or sources. It is also necessary to take into account the total cost of ownership, which includes not only the original cost of materials but also expenses related to processing, finishing, and upkeep over the product’s lifespan. Manufacturers can maximize value without sacrificing quality or performance by carefully weighing material selections and the expenses associated with them.

Surface Finish and Tolerances

The material used should be capable of producing the desired surface finish and dimensional tolerances for the part. Some materials may have better surface finish qualities, which allow for smoother surfaces and tighter tolerances without requiring extensive post-processing. The simplicity and viability of attaining particular surface finishes and tolerances can be greatly impacted by the material selection. For example, materials with good machinability and low effort requirements for exact surface finishes include stainless steel and some polymers. However, it may be difficult to achieve tight tolerances and the appropriate surface finishes when working with extremely abrasive materials or those that are prone to warping during milling. Dimensional stability over time can also be impacted by the material’s stability in various environmental settings, such as temperature and humidity. Therefore, it is essential to choose a material that complies with the required dimensional tolerances and surface finish criteria to achieve quality standards and guarantee the finished product’s operation.

Environmental Factors

Environmental considerations include corrosion resistance, chemical stability, and temperature resistance, which are especially important for parts that operate in harsh or demanding environments. Choosing materials that can withstand environmental conditions improves the durability and dependability of CNC components.

Environmental aspects also include sustainability issues, which motivate the use of environmentally friendly materials and production techniques. Choosing materials with the least possible environmental impact and supporting recycling and reuse programs are crucial at a time when environmental responsibility is becoming more and more important. In addition to lessening their influence on the environment, sustainable materials also support business sustainability objectives and consumer preferences for eco-friendly goods. Manufacturers can enhance their competitiveness by giving priority to materials with excellent environmental performance and help the global movement towards a more sustainable future.

Common Materials Used in CNC Machining

While the selection of materials for CNC machining is extensive, a few standouts dominate the production landscape:

Metals

Aluminum, steel, stainless steel, titanium, and copper are commonly used in CNC machining due to their good mechanical qualities, thermal conductivity, and durability. Aluminum alloys, in particular, are valued for their lightweight yet strong properties, making them perfect for aerospace, automotive, and consumer electronics applications. When it comes to CNC machining, metals are versatile since each type has special qualities that make them suitable for certain uses. Steel is widely used in structural parts for infrastructure and machinery because of its great strength and durability. Since stainless steel doesn’t corrode, it’s the perfect material for parts that are exposed to hostile environments, such as chemical processing or marine equipment. Titanium is preferred in the sporting goods, medical, and aerospace industries due to its remarkable strength-to-weight ratio and biocompatibility. Copper is prized in heat exchangers and plumbing fittings due to its great electrical conductivity, which makes it essential for electrical and electronic components. CNC producers can customize the material selection to meet unique application demands and performance criteria because of the variety of metal possibilities available.

Plastics

Plastics are versatile, affordable, and easy to machine, making them ideal for a wide range of CNC parts. Acrylic, polycarbonate, ABS (Acrylonitrile Butadiene Styrene), and nylon are popular materials with qualities such as transparency, impact resistance, and chemical stability. Plastics satisfy a wide range of functional and aesthetic needs and provide an abundance of possibilities for CNC machining. Acrylic is used in signage, exhibition cases, and architectural features. It is valued for its optical clarity and weather resistance. Because of its reputation for impact resistance and transparency, polycarbonate is used extensively in electronic enclosures, safety equipment, and automobile parts. Preferred for its robustness, stiffness, and simplicity in post-processing, ABS finds widespread application in consumer items, automobile interiors, and prototyping. Given its durability, low coefficient of friction, and chemical resistance, nylon is an essential material for gears, bearings, and structural parts. Plastics can be machined precisely and consistently to create complicated parts for a variety of sectors. This gives producers flexibility in choosing materials to fulfill a range of design criteria.

Composites

These are materials that combine the strength and stiffness of fibers with the versatility of polymers. Examples include carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers. These materials find use in the aerospace, automotive, and sporting goods industries, where lightweight and high strength-to-weight ratios are important. Given their special combination of qualities, composites are becoming more and more common in CNC machining applications. Because of their remarkable strength-to-weight ratios, carbon fiber-reinforced polymers (CFRP) and fiberglass-reinforced polymers are perfect for parts where weight reduction is crucial, like airplane fuselages, car body panels, and high-performance sports equipment. Depending on the demands of a given application, designers can optimize strength, stiffness, and impact resistance thanks to the directed alignment of fibers inside the matrix, which enables customizable mechanical properties.

Ceramics

Ceramics have outstanding hardness, wear resistance, and temperature stability, making them ideal for demanding applications in the aerospace, medical, and industrial fields. While ceramics are notoriously difficult to mill due to their brittle nature, modern CNC techniques and tools have made ceramic machining more viable. Furthermore, ceramics have outstanding thermal and electrical insulation qualities, which makes them invaluable for electrical insulation applications and high-temperature settings.

Ceramic materials with high abrasion resistance and chemical inertness, such as silicon carbide and aluminum oxide, are frequently employed in cutting tools, wear-resistant components, and chemical processing equipment. To overcome the difficulties involved with ceramic machining, sophisticated techniques like ultrasonic and laser-assisted machining have been developed. These techniques allow for the fabrication of exact features and complex shapes with the least amount of tool wear. Ceramics remain the material of choice for CNC machining in critical applications where performance is crucial since industries seek materials that can survive harsh environments while retaining dimensional stability and reliability.

Exotic Alloys

Inconel, Monel, and Hastelloy are used in specific applications that require high-performance characteristics. These high-performance materials provide improved corrosion resistance, high-temperature strength, and outstanding mechanical qualities, but at a higher cost and machining complexity. Their extensive use goes beyond conventional industrial environments, as cutting-edge technologies take advantage of their special qualities to provide creative solutions. More and more, Inconel, Monel, and Hastelloy are being used in cutting-edge industries like renewable energy, where their ability to withstand extreme conditions is essential for parts like solar panels, wind turbines, and hydrogen fuel cells. Furthermore, the development of additive printing techniques has created new opportunities for the optimization and customisation of these unusual alloys, allowing complex designs with improved performance characteristics to be created. Because of these unusual alloys’ adaptability and dependability, research and development efforts to push the boundaries of material science will continue, and their significance in forming future technologies will be long-lasting.

Conclusion

In the field of CNC machining, material selection is essential in influencing the performance, quality, and cost-effectiveness of manufactured parts. Manufacturers can optimize the production process and produce greater results by understanding the distinct qualities and requirements of different materials. Whether it’s balancing strength and weight in aircraft components or maximizing cost-effectiveness in consumer electronics, using the correct materials ensures that CNC parts satisfy the highest precision and reliability standards. As technology and material science develop, the search for the ideal material for CNC machining continues, fueling innovation and pushing the limits of manufacturing excellence.

BUSINESS

Know Your Rights: A Citizen’s Guide to Legal Protections

Introduction

Understanding your constitutional rights during interactions with law enforcement is essential for every citizen. This guide provides an overview of key legal protections guaranteed by the U.S. Constitution and relevant case law. While this information serves as a general educational resource, it is not a substitute for personalized legal advice from a qualified attorney.

The Fourth Amendment: Protection Against Unreasonable Searches and Seizures

The Fourth Amendment protects citizens against unreasonable searches and seizures by government officials, including police officers. This means:

- Warrant Requirement: In most cases, police need a warrant to search your home, vehicle, or personal belongings.

- Probable Cause: For a warrant to be issued, officers must demonstrate probable cause that evidence of a crime will be found.

- Exceptions: Several exceptions exist, including:

- Consent searches

- Plain view doctrine

- Searches incident to a lawful arrest

- Automobile exception (with probable cause)

- Exigent circumstances (emergencies)

The Fifth Amendment: Protection Against Self-Incrimination

The Fifth Amendment includes several important protections, most notably the right against self-incrimination:

- Right to Remain Silent: You cannot be compelled to provide testimony that might incriminate yourself.

- Miranda Rights: If you are in custody and being interrogated, officers must inform you of your rights to:

- Remain silent

- Be informed that anything you say can be used against you

- Have an attorney present during questioning

- Have an attorney appointed if you cannot afford one

The Sixth Amendment: Right to Counsel

The Sixth Amendment guarantees the right to legal representation:

- Right to an Attorney: You have the right to be represented by an attorney in all criminal proceedings.

- Public Defenders: If you cannot afford an attorney, one will be appointed to represent you.

- When the Right Attaches: This right begins at critical stages of prosecution, starting with formal charges.

During Police Encounters: Know Your Rights

Traffic Stops

- Remain calm and keep your hands visible.

- You must provide your license, registration, and proof of insurance when requested.

- You have the right to remain silent beyond providing basic identifying information.

- You may refuse consent to search your vehicle, but officers may search if they have probable cause.

- You are not required to answer questions about where you’re going or where you’ve been.

Street Encounters

- Ask if you are free to leave. If yes, you may calmly walk away.

- If detained, you have the right to know why you are being detained.

- You do not have to consent to a search of your person or belongings, though officers may conduct a limited pat-down for weapons if they have reasonable suspicion.

- Remaining silent cannot be used as evidence of guilt.

Home Encounters

- You do not have to open your door for police unless they have a warrant.

- You may ask to see the warrant before allowing entry.

- If officers have a valid search warrant, you should not interfere with their search, but you can observe and take notes.

- Without a warrant, you can deny entry (with some exceptions for emergency situations).

How to Exercise Your Rights

When Interacting with Police

- Stay calm and be respectful. Hostility can escalate situations unnecessarily.

- Clearly state that you are exercising your rights. For example: “I do not consent to a search” or “I am exercising my right to remain silent.”

- Ask if you are free to leave. If not, ask why you are being detained.

- Request an attorney immediately if arrested. Say clearly: “I want to speak with an attorney.”

- Do not resist arrest, even if you believe the arrest is unlawful. Legal challenges should be made in court, not on the street.

Documenting the Encounter

- Mental notes: Remember officer names, badge numbers, patrol car numbers.

- Witnesses: Note if there are witnesses to the interaction.

- Written record: As soon as possible, write down everything you remember.

- Medical attention: Seek medical attention immediately if injured and document all injuries.

When Professional Legal Help Is Necessary

While understanding your rights is crucial, navigating the legal system requires professional expertise in many situations:

- If you’ve been arrested or charged with a crime

- If your rights have been violated

- If you’re unsure about the legality of police actions

- Before making any statements to police in a criminal investigation

Finding the Right Legal Representation

- Criminal defense specialists have specific expertise in protecting citizens’ rights during criminal proceedings.

- Legal aid organizations can provide representation if you cannot afford an attorney.

- Bar association referrals can help you find qualified attorneys in your area.

- Public defenders are trained specifically in criminal defense.

Important Disclaimer

This guide provides general information about legal principles and is not legal advice tailored to specific situations. Laws vary by state and locality, and legal precedents evolve over time. Always consult with a qualified attorney for advice about your specific circumstances.

Resources for Further Information

- American Civil Liberties Union (ACLU): www.aclu.org

- National Legal Aid & Defender Association: www.nlada.org

- American Bar Association: www.americanbar.org

- State and local bar associations

- Legal aid organizations in your community

Conclusion

Knowledge of your constitutional rights is an essential component of citizenship, but it is only the first step. When facing serious legal situations, professional legal counsel is invaluable. Criminal law specialists are trained to navigate the complexities of the legal system and provide the personalized guidance necessary to protect your rights and interests.

Remember: The best protection is a combination of knowledge, calm assertion of your rights, and appropriate professional legal representation when needed.

BUSINESS

Pet Parent Guilt: Balancing Work Demands and Your Dog’s Wellbeing

Those sad puppy eyes watching you grab your keys. The excited welcome home that makes you wonder what they’ve been doing all day. For many working dog owners, the emotional tug-of-war between professional responsibilities and pet parenting creates a unique form of guilt that can be surprisingly intense.

Understanding Pet Parent Guilt

Pet parent guilt is a real phenomenon affecting millions of working dog owners. This feeling stems from our deep bonds with our canine companions and our awareness that dogs are social creatures who thrive on interaction. When work demands pull us away for eight, ten, or more hours daily, that nagging voice inside asks: “Am I being fair to my four-legged family member?”

Research from the American Pet Products Association shows that over 65% of dog owners report feeling some level of guilt about leaving their pets alone while at work. This guilt often manifests when:

- Your dog gives you “the look” as you prepare to leave

- You work longer hours than expected

- You see signs of separation anxiety in your pet

- You miss opportunities to exercise or socialize your dog

- You compare yourself to seemingly more available pet parents

The Impact on Your Dog’s Wellbeing

Understanding what dogs genuinely need helps separate valid concerns from unnecessary guilt. Dogs require:

- Regular physical exercise appropriate to their breed, age, and health

- Mental stimulation through play, training, and environmental enrichment

- Social interaction with humans and, for many dogs, other canines

- Consistent feeding, bathroom breaks, and healthcare

- A safe, comfortable environment

While dogs do form strong attachments to their owners, many can adapt well to reasonable alone time when properly supported. The key is recognizing when your absence genuinely impacts your dog’s wellbeing versus when your guilt might be more about human emotions than canine needs.

Practical Solutions for Working Pet Parents

Schedule Management

- Establish a consistent routine: Dogs thrive on predictability. Regular wake-up, feeding, walking, and bedtime schedules provide security.

- Build in quality time: Even 15-30 minutes of focused interaction before and after work can significantly impact your dog’s wellbeing.

- Incorporate your dog into workouts: A morning run or evening walk serves both your health goals and your dog’s exercise needs.

During-Work Support

- Professional dog walkers: Mid-day visits break up long periods alone and provide exercise and bathroom breaks.

- Doggy daycare: For highly social dogs, structured daycare environments offer stimulation and companionship.

- Pet sitters: In-home care provides personalized attention in your dog’s familiar environment.

- Tech solutions: Pet cameras allow check-ins throughout the day, and some dispense treats or allow two-way communication.

- Neighbor exchanges: Arrange with neighbors to check on each other’s pets during workdays.

Home Environment Optimization

- Enrichment toys: Puzzle feeders, stuffed Kongs, and interactive toys provide mental stimulation.

- Rotating toy selection: Keep a variety of toys but only make a few available each day to maintain novelty.

- Comfortable resting areas: Multiple beds throughout the home give options for your dog.

- Natural light and views: Position beds near windows so your dog can observe outdoor activity.

- Calming influences: Leaving on gentle music or television provides background noise that mimics human presence.

Flexible Work Arrangements

- Remote work options: Even one or two work-from-home days weekly can reduce your dog’s alone time.

- Pet-friendly workplaces: Some employers now welcome well-behaved dogs in the office.

- Lunch break visits: If you live close enough, brief mid-day home visits can break up your dog’s day.

Signs Your Dog May Need More Support

While some guilt is natural, recognize when your dog might genuinely need additional attention:

- Destructive behavior that occurs primarily during your absence

- Excessive barking or howling when alone

- House-training regression

- Changes in eating or drinking habits

- Excessive excitement upon reunions

- Depression or lethargy

- Excessive licking, chewing, or other repetitive behaviors

If you notice these symptoms, consulting with a veterinarian or animal behaviorist can help determine if your dog has separation anxiety requiring specific intervention.

Self-Care for Guilty Pet Parents

Managing your own emotions is equally important:

- Practice perspective: Remember that quality of interaction often matters more than quantity.

- Address specific concerns: If you identify concrete issues (like insufficient exercise), develop targeted solutions rather than dwelling on general guilt.

- Connect with other working pet parents: Sharing experiences and solutions builds community and normalizes challenges.

- Celebrate successes: Acknowledge what you’re doing right rather than focusing solely on perceived shortcomings.

- Avoid social media comparison: Carefully curated Instagram feeds rarely reflect the everyday reality of pet ownership.

Building a Balanced Relationship

The most healthy human-canine relationship acknowledges both species’ needs. Dogs contribute tremendously to our emotional wellbeing, providing companionship, stress relief, and unconditional love. In return, we provide care, structure, and affection within the constraints of modern living.

Rather than viewing work and pet parenting as opposing forces, consider how they can complement each other. The structure your work schedule provides can benefit your dog, while your pet’s needs encourage healthy breaks and work-life boundaries that might otherwise be neglected.

With thoughtful planning, appropriate support systems, and a realistic perspective, both you and your canine companion can thrive despite—and sometimes because of—the balance you’ve created between professional responsibilities and pet parenting.

Remember: Your dog doesn’t need you present every minute to be happy—they need you present in the moments that matter most.

BUSINESS

Preventing Career-Ending Injuries: Professional Strategies for Amateur Athletes

In the world of amateur athletics, the passion for sport often outpaces the knowledge of how to train safely. While professionals have teams of specialists monitoring their every move, recreational athletes typically navigate their fitness journeys alone. Yet, the risk of career-ending injuries doesn’t discriminate between paid professionals and weekend warriors.

This article explores evidence-based strategies used by elite athletes that amateur sports enthusiasts can adopt to extend their athletic lifespans and prevent devastating injuries.

Understanding the Professional Approach

Professional athletes don’t just train harder—they train smarter. Their injury prevention strategies are built on several key pillars:

- Personalized programming

- Proactive physical therapy integration

- Recovery prioritization

- Biomechanical optimization

- Progressive loading

Let’s explore how recreational athletes can implement these professional-grade strategies.

Physical Therapy: From Reactive to Proactive

The Professional Model

For professionals, physical therapists aren’t just for rehabilitation—they’re integral to injury prevention. Teams like the NBA’s Phoenix Suns employ full-time physical therapists who screen athletes for movement deficiencies before problems arise.

“The old model was waiting until something breaks and then fixing it,” explains Dr. James Andrews, renowned orthopedic surgeon to professional athletes. “The new model is identifying weaknesses before they become injuries.”

Amateur Application

While you may not have a personal PT, you can adopt this proactive approach:

- Schedule a preventative screening: Many physical therapy practices offer movement assessments specifically for athletes. These evaluations identify muscle imbalances, mobility restrictions, and movement patterns that could lead to injury.

- Learn self-assessment techniques: Physical therapists can teach you how to regularly check for warning signs like asymmetries in strength or mobility between sides of your body.

- Build a relationship before injury: Establish care with a sports-focused physical therapist during healthy periods, making them familiar with your baseline if problems arise.

- Implement “prehab” exercises: Work with a PT to develop sport-specific preventative exercises that address your individual risk factors.

Movement Quality Over Quantity

The Professional Standard

Elite athletes don’t measure workouts purely by volume or intensity but by movement quality. This is why you’ll see Olympic weightlifters spending hours perfecting technique with PVC pipes before touching heavy barbells.

Amateur Application

- Master fundamentals before progression: Ensure proper form in basic movements before advancing to more complex or intense variations.

- Video analysis: Record yourself performing key movements in your sport and compare them to professional examples, or share them with a coach or physical therapist.

- Rate of perceived exertion (RPE): Use the 1-10 RPE scale to ensure you’re not training at maximum intensity too frequently. Professionals rarely train above an 8/10 intensity more than 1-2 times weekly.

- Movement screens: Incorporate simple assessments like the Functional Movement Screen (FMS) or Y-Balance Test that physical therapists use to identify risky movement patterns.

Periodization: Strategic Training Cycles

The Professional Approach

Professional training is meticulously planned in cycles with varying intensities and focuses—a practice called periodization. This prevents overtraining and allows for strategic recovery.

Amateur Application

- Plan seasonal training: Work with a knowledgeable coach or physical therapist to divide your year into preparatory, competitive, and recovery phases.

- Deload weeks: Incorporate planned reduction weeks (typically 25-40% lower volume) every 4-6 weeks of training.

- Sport-specific timing: Consult with a physical therapist to identify when your sport places the highest injury risk and adjust training accordingly.

- Training diary: Track volume, intensity, and how your body responds to identify patterns that might predict injury.

Recovery: The Professional Secret

The Elite Standard

Recovery isn’t what professionals do when they’re not training—it’s an equal training priority. The U.S. Olympic Training Center dedicates as much space to recovery facilities as to training ones.

Amateur Implementation

- Sleep optimization: Target 7-9 hours of quality sleep, as research shows injury rates increase by 1.7 times when athletes sleep less than 8 hours.

- Active recovery protocols: Work with a physical therapist to develop appropriate active recovery sessions (light movement that promotes blood flow without creating additional fatigue).

- Compression therapy: Use compression garments post-exercise as studies show they can reduce muscle soreness and accelerate recovery.

- Contrast therapy: Alternate between hot and cold exposure (under guidance from a physical therapist) to reduce inflammation and enhance recovery.

- Nutrition timing: Consume protein and carbohydrates within the “golden window” (30-60 minutes post-exercise) to optimize recovery.

Strength Training: Beyond Sport-Specific Work

The Professional Edge

Nearly every professional sport now emphasizes comprehensive strength training—even endurance athletes. This focus builds resilience in tendons, ligaments, and muscles that sport-specific training alone cannot develop.

Amateur Application

- Functional assessment: Work with a physical therapist to identify the key movement patterns and muscle groups that need strengthening for your sport.

- Resistance training fundamentals: Include compound movements like squats, hinges, pulls, and presses at appropriate intensities for your experience level.

- Tendon-strengthening protocols: Incorporate slow eccentric training (the lowering phase of movements) as research shows this specifically strengthens tendons, reducing injury risk.

- Balance correction: Use physical therapy assessments to identify and correct strength imbalances between:

- Agonist/antagonist muscle groups (e.g., quadriceps/hamstrings)

- Dominant/non-dominant sides

- Prime movers vs. stabilizers

Mobility vs. Flexibility: The Professional Distinction

The Elite Understanding

Professionals distinguish between static flexibility (how far a muscle can stretch) and dynamic mobility (control throughout a range of motion). The latter is far more protective against injury.

Amateur Approach

- Joint-by-joint assessment: Work with a physical therapist to identify which joints need more mobility versus stability.

- Dynamic warm-ups: Replace static stretching before activity with dynamic mobility drills that physical therapists recommend for your sport.

- Movement pattern specificity: Focus mobility work on ranges of motion specific to your sport rather than general flexibility.

- Neurological training: Include proprioceptive exercises that improve your nervous system’s awareness of joint position.

The Importance of Load Management

The Professional System

Elite athletes carefully monitor training load—both external (volume, intensity, frequency) and internal (how their bodies respond). This helps identify when they’re approaching injury thresholds.

Amateur Implementation

- Progressive overload: Increase training volume by no more than 10% per week, a guideline supported by injury prevention research.

- Acute:Chronic Workload Ratio: Track your weekly training load compared to your 4-week average, keeping the ratio between 0.8-1.3 to minimize injury risk.

- Intensity distribution: Work with a physical therapist to determine appropriate training intensity distributions (e.g., 80% low intensity, 20% high intensity).

- Monitoring tools: Use simple metrics like morning resting heart rate, perceived recovery scores, or grip strength tests to identify recovery status.

Environment and Equipment Considerations

The Professional Standard

Professionals optimize every environmental factor—from playing surfaces to equipment fit—to minimize injury risk.

Amateur Application

- Footwear assessment: Consult with a physical therapist or specialized running store for proper footwear that matches your biomechanics and sport.

- Surface progression: Gradually adapt to different playing surfaces rather than making sudden changes.

- Equipment fitting: Invest in properly sized equipment with guidance from knowledgeable professionals.

- Training environment assessment: Evaluate your training spaces for hazards that professionals would never tolerate.

Psychological Factors in Injury Prevention

The Professional Mindset

Elite athletes recognize that psychological states significantly impact injury risk. Research shows that stress, anxiety, and poor focus all correlate with higher injury rates.

Amateur Implementation

- Stress management techniques: Incorporate mindfulness practices, breathing exercises, or other stress-reduction methods recommended by sports psychologists.

- Pre-performance routines: Develop consistent routines that help maintain focus during high-risk activities.

- Realistic goal-setting: Work with coaches or physical therapists to set appropriate progression timelines that don’t encourage risky behavior.

- Risk assessment training: Learn to honestly evaluate when pushing through discomfort becomes dangerous.

Building Your Prevention Team

The Professional Model

No professional athlete relies solely on themselves for injury prevention—they have integrated teams of specialists.

Amateur Approach

- Find a sports-focused physical therapist: This professional should be your cornerstone for injury prevention.

- Consider periodic coaching: Even occasional sessions with qualified coaches can correct technique issues before they become problematic.

- Connect with knowledgeable training partners: Train with others who prioritize longevity over short-term achievements.

- Leverage technology: Use apps and devices that provide objective feedback on movement quality, recovery status, and training loads.

Conclusion: A Career-Extending Mindset

The most valuable professional strategy amateur athletes can adopt isn’t a specific exercise or recovery technique—it’s a mindset shift from short-term performance to long-term athletic sustainability.

By implementing these professional-grade preventative strategies and working proactively with physical therapy professionals, recreational athletes can dramatically reduce their injury risk while improving performance. The result isn’t just avoiding career-ending injuries but extending your athletic journey for decades to come.

Remember that professionals view injury prevention not as something separate from training but as an integral component of athletic development. By adopting this perspective and these strategies, you’re not just training like a professional—you’re maximizing your athletic lifespan like one too.

-

GENERAL1 year ago

GENERAL1 year agoDiscovering the Artistic Brilliance of Derpixon: A Deep Dive into their Animation and Illustration

-

Posts1 year ago

Posts1 year agoSiegel, Cooper & Co.

-

Lifestyle1 year ago

Lifestyle1 year agoPurenudism.com: Unveiling the Beauty of Naturist Lifestyle

-

Lifestyle1 year ago

Lifestyle1 year agoBaddieHub: Unleashing Confidence and Style in the Ultimate Gathering Spot for the Baddie Lifestyle

-

HEALTH1 year ago

HEALTH1 year agoTransformative Health Solutions: Unveiling the Breakthroughs of 10x Health

-

Entertainment1 year ago

Entertainment1 year agoKhatrimaza Unveiled: Exploring Cinematic Marvels and Entertainment Extravaganza

-

Entertainment1 year ago

Entertainment1 year agoGeekzilla Podcast: Navigating the World of Pop Culture, Gaming, and Tech

-

BUSINESS1 year ago

BUSINESS1 year agoUnlocking the Secrets to Jacqueline Tortorice Remarkable Career and Accomplishments